By Matthew Sands

When commercial aquatics facility managers and operators find themselves confronted with peeling, cracking or leaking pools, a viable solution is to line these pools with a reinforced PVC pool interior as it provides a complete waterproofing solution. Traditionally, the material colors used in commercial applications have been white and blue with the use of black for racing lanes and transitions. However, there are many new colors with subtle patterns and textures that imitate the look of gunite, slate, marble and sand. Additionally, these new designs are available with additional texture for a superior bathing experience. These membranes are offered not only in 60mil but also in 70 and 80mil reinforced membrane options for maximum durability.

For attractiveness’ sake, the reinforced PVC pool interior is available in various textures and prints that resemble marble, stone and sand. These options have been popular with hotels, country clubs, homeowners associations and community pools because they provide a high-end feel, going beyond the plain white or blue, while enhancing safety through the slip resistance offered by textures.

Choosing PVC Pool Interiors

While price is always a consideration, most facility managers and operators find reinforced PVC pool interiors very affordable. When considering this option, it’s important to consider the costs of refinishing or repairing the pool versus the cost of installing reinforced PVC. Some underlying issues with a pool’s structure can be eliminated by using a reinforced PVC pool interior to create a complete watertight structure throughout the pool.

These pool interiors completely seal the structure of the pool and keep it watertight, making it suitable for both renovating existing pools and building new pools. They are not susceptible to deterioration from acidic water conditions. Commercial-grade reinforced PVC pool interiors are coated with a protective lacquer that enhances durability to resist tears, chemical abuse, water absorption and UV resilience.

These products also offer another, more immediate benefit: Rather than dealing with long lead times for premanufactured products, reinforced PVC pool interior materials are readily available. Installers can overcome lead times by stocking this material, which is welded on the pool site.

This weld-in-place reinforced PVC is uniquely able to provide a perfect fit for pools because the liners are installed on-site, providing a custom fit, even for the most challenging shapes.

Once the reinforced PVC interior is installed, the surface underneath can continue to shift and crack, but it won’t affect the reinforced PVC pool interior.

Understanding Installation

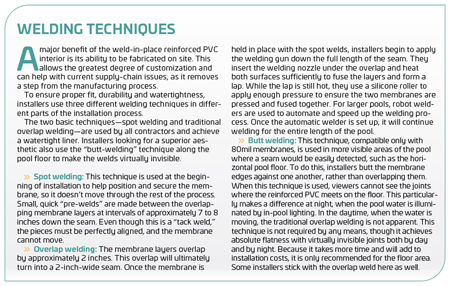

The installation process is relatively straightforward. Before the on-site welding of the reinforced PVC pool interior begins, crews must prepare the surface, which can include repairs. Most pools require a day or less for preparation. However, if a pool is in particularly bad shape, a professional might need to spend three to four days patching the pool, fixing returns, etc.

Once the pool surface is prepared, a felt lining is installed along the floor and walls of the pool structure. This material, also referred to as geotextile, acts as an antibacterial to avoid bacteria proliferation behind the reinforced PVC and extends the life of the product. As a side benefit, the felt lining makes the floor more comfortable to stand on. This is especially beneficial to older bathers using the pool for water conditioning, therapy or aerobics. Patrons at small wading pools that feature a reinforced PVC interior regularly report that they love the cushioned feeling of the surface.

After the lining is installed, 6-foot-wide strips of reinforced PVC are rolled out and heat-welded together on site to ensure a perfect, smooth fit. Steps, beach entries, safety ledges and the like are cut, fitted and welded as well.

Some reinforced PVC pool interiors are available with slip-resistant, embossed surfaces, which are generally used on steps, in shallow areas and beach entries. Black material is also available to create racing lanes, transitions and depth markers as needed.

On the Rise

The awareness of reinforced PVC pool interiors is definitely on the rise, especially among commercial aquatics facilities. In fact, many architects and aquatic consultants now are starting to require the use of reinforced PVC in high-rises or anywhere the waterproofing of the pool must be guaranteed.

As a result, pool professionals are finding it even easier to suggest, sell, install and outsource the installation of these membranes to commercial pools. The new colors, textures and finishes of this reinforced PVC pool interior is so beautifully striking, so practical and so long-lasting that it is quickly becoming a preferred pool interior option for commercial aquatic facilities, health and country clubs or any community pool that wants a beautiful architectural upgrade while also renovating their pool interior. RM

ABOUT THE AUTHOR

Matthew Sands is sales engineer for Renolit, a manufacturer of plastics-based construction products, including weld-in-place, reinforced-PVC membrane liners for swimming pools, with U.S. headquarters in LaPorte, Ind. He has more than a decade of experience in the construction renovation sector of the company.